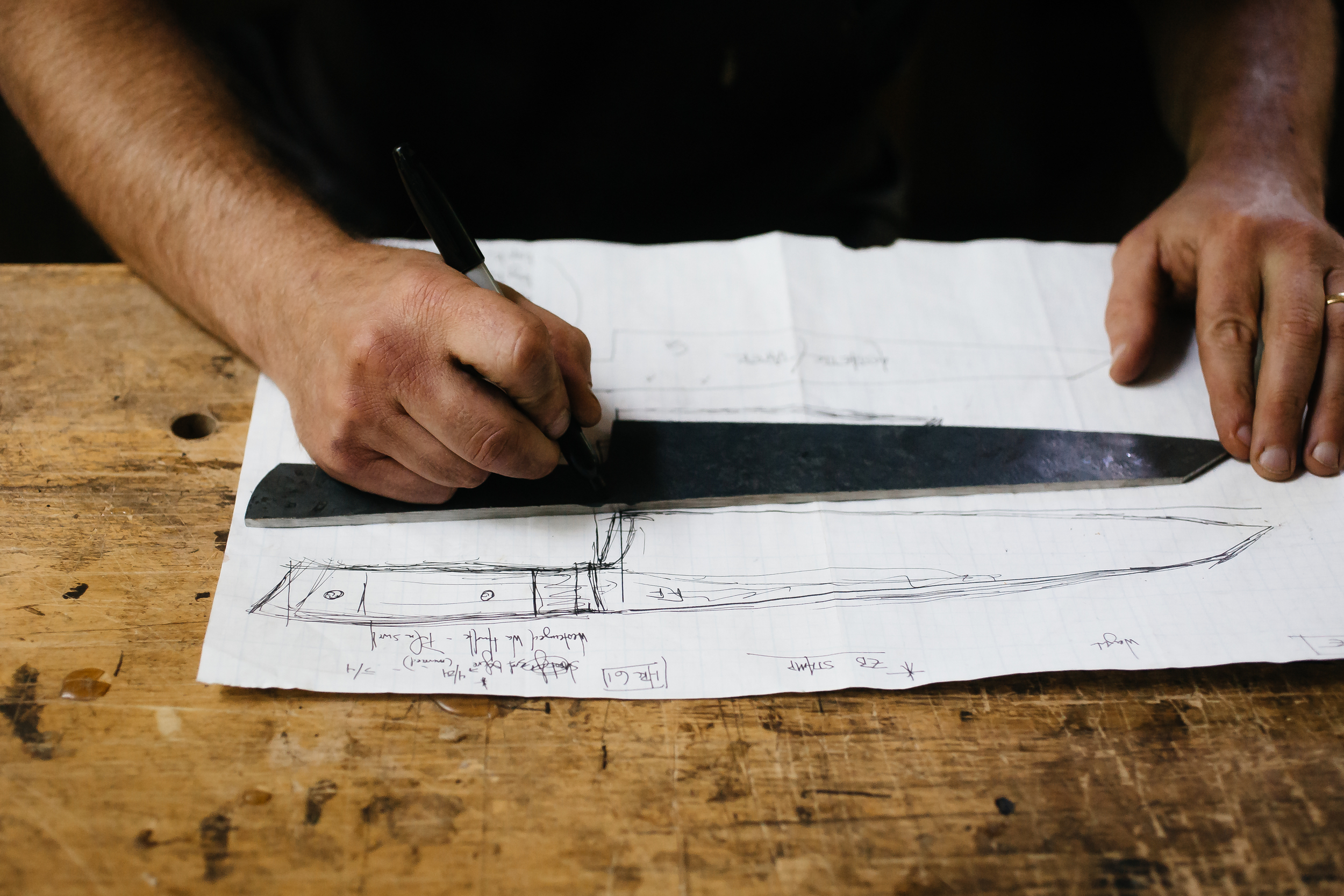

Process

using recycled steels: Why reclaim materials when there are new ones?

We believe in recycling and repurposing materials and you will notice that instead of incorporating the rare in our knives, we specialize in identifying interest in the everyday or ignored. At our volume, using recycled steel is not cheaper than buying new steel; however, these materials allow us to impart interest and story into each blade. Recycled steel also increases the uniqueness of each piece and forces us to be innovative and flexible with our limited supply of each material. Finally, finding materials is nearly impossible without the supportive people who have come alongside us, and we like that it forces us to depend on our community.

the Known or the Unknown

Known Steels

When a knifemaker considers steel sources, he or she must consider the known and the unknown costs, the pros and the cons, and his or her level of experience. Known steels offer a number of benefits: If one knows the steel one has, following a heat treatment recipe and getting the most out of that steel is much easier. Additionally, one does not need to spend time finding, gathering, and testing the unknown steels; instead, one can spend that time honing one's skills. We suggest anyone just getting into knife making should start with known steels and get to know one or two alloys very well.

Unknown Steels

While more difficult and time-intensive, using recycled steel can be very rewarding. Recycled steels connect our knives to history and humanity and give us even more pleasure in the production of our knives. The heat treatment of steel, however, is essential, complex, and not to be underestimated in the production of a blade; one must be a constant student and ever vigilant when using steel from recycled sources. To be confident in the quality of our knives, we have invested in a Rockwell hardness tester, and we also perform a battery of qualitative tests on each steel and heat treatment. Even after this in-house testing, we pay a metallurgical lab to analyze the steels from our sources so that we know their full chemical breakdown. This intense process allows us to tailor an ideal heat treatment approach for each alloy to maximize the performance of each knife. We strive to build the highest performance blades possible, and the many alloys we find in recycled sources help us achieve this goal. But, when we do not have an alloy that is ideal for a specific application, we do not compromise on performance. Instead, we purchase an appropriate alloy until we find a recycled source that gives us comparable performance. Clearly, using recycled steels is a much more complex process than using purchased steels, and it is not for everyone. But for us, because of the history and people to which it connects us, the lessened environmental impact, and the knives it allows us to make, it's worth it.

Steps of Knife making

Warning: the Steps of Knifemaking below is for everyone, but particularly for those who want to go full nerd. We use terms like martensite, lamellar anneal, and normalization. If you are an aspiring knifemaker, we hope this section will be a helpful resource. If you are not an aspiring knifemaker but want to look at some pretty pictures, those are here, too. And, you will probably learn something in the process! :)

Knife Making Lexicon

If you are interested in finding out more about the terms and practices of knife making, you may want to check out the guide we put together below.