THE JULY SALE IS CLOSED!

YOU MAY VIEW THE KNIVES FROM OUR JULY SALE BELOW, THOUGH THEY ARE NO LONGER AVAILABLE.

Here are some notes for this month’s study in gyutos:

At Bloodroot, we depart with the traditional Japanese method of building gyutos in a number of important ways:

First, we attach our handles to the blade with epoxy and consider the handle of the knife as an important and valuable component of its construction. We are also not so fussy about polishing our knives after each use and like the patina that develops because it actually protects the knife from rust and reduces reactivity with food.

We use stabilized woods. The stabilization process makes the handle a lot more forgiving of heat and moisture, so it won't move around so much. It also allows us to use beautiful woods that would not be suitable for knife handles without this treatment and gives the handles longevity.

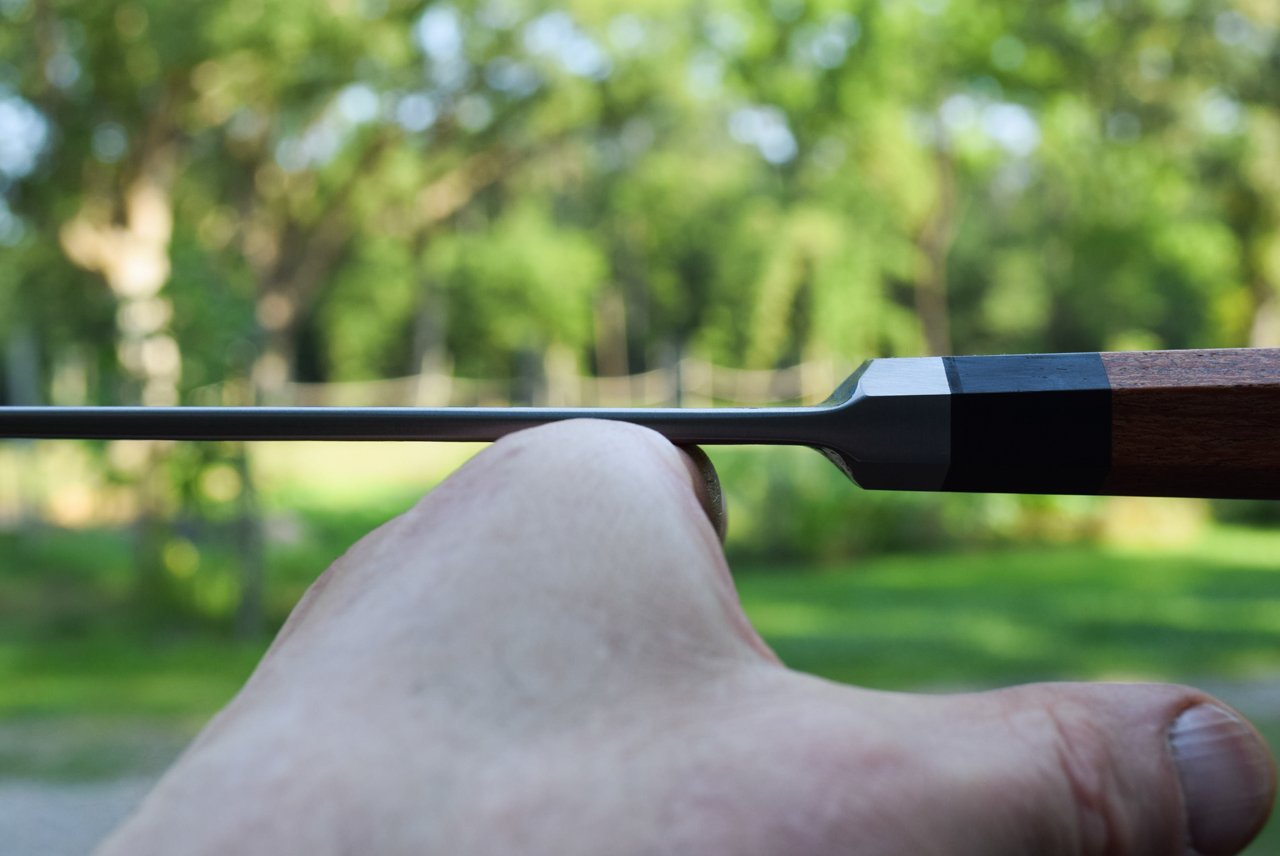

We grind in a distal taper so that you can use our knives for fine tip work. So Frenching an onion with our gyuto is a pleasant process rather than an achievement.

We use monosteel or Damascus instead of san mai (cladding) and test each batch of knives for hardness to help check that our heat-treatment achieved the results we were shooting for. While hardness testing is by no means the end-all source of information, a soft cladding makes this testing impossible.

We will cover heat-treatment in another dive, but dialing in the heat-treatment allows for relatively tough knives that will also hold their edges and most critically, allows the knife to be ground thinner which makes cutting much more efficient and sharpening much easier. We think this approach to heat treatment is an improvement to the heat treatment of the standard French chef as well as the gyuto - we are able to marry much of the durability of one with the edge holding and precision of the other.

Phew. That was a lot, kids. Let's look at some knives!!

195mm Cocobolo Oak Gyuto

Blade: Sawblade @HRC 64.

Handle: Cocobolo ferrule, octagonal oak handle.

Notes: 162g. 46mm deep. This is our take on a traditional gyuto. We even used wood from Japan, but, true to form, we also used a bit of Cocobolo :)

Sources: Steel - Granite-cutting sawblade, Elberton, Ga.

Cocobolo - Oneta Woodworks, Athens, Ga.

Oak - held up a destroyer while it was docked in Yokosuka, Japan.

Price: $675

225mm Cherry Burl Gyuto

Blade: Roller Bearing @HRC 64.

Handle: Octagonal integral cherry burl handle with redwood and leather spacers.

Notes: 196g. 52mm deep. This version has a finer tip and a bit of a slant in the heel, reminiscent of some French chefs.

Sources: Steel - Roller bearing, machine shop, Birmingham, Alabama.

Redwood - Watkinsville, Ga, customer gift.

Price: $1025

210mm Mesquite Deep Gyuto

Blade: Roller Bearing @HRC 64.

Handle: Westernized octagonal integral mesquite handle with blackwood and leather spacers.

Notes: 216g. 54mm deep. More of a traditional shape with retained forge marks and a Westernized octagonal handle. And Mesquite to add a bit of Texas flavor. You know, Texas + Paris.

Sources: Steel - Roller bearing, machine shop, Birmingham, Alabama.

Mesquite - Texas.

Blackwood - cast offs, clarinet factory, Paris.

Price: $1075

205mm Mulberry K-tip Gyuto

Blade: Roller Bearing @HRC 64.

Handle: Octagonal integral mulberry handle with leather and brass spacers.

Notes: 185g. 50mm deep. A tapered K(iritsuke)-tip with a strong curve into the the tip.

Sources: Steel - Roller bearing, machine shop, Birmingham, Alabama.

Mulberry - Arnoldsville, Ga.

Price: $1025

200mm Walnut Gyuto

Blade: Roller Bearing @HRC 64.

Handle: Westernized octagonal integral walnut handle with leather and copper spacers.

Notes: 217g. 50mm deep. Another traditional shape with a walnut handle and integral construction.

Sources: Steel - Roller bearing, machine shop, Birmingham, Alabama.

Walnut - Waters Edge Woods, Athens, Ga.

Price: $1025

195mm Walnut Gyuto

Blade: Roller Bearing @HRC 64.

Handle: Integral walnut right-handed d-handle with leather and fiber spacers.

Notes: 166g. 46mm deep. This knife has a polished finish, a moderated tip and a high-handed d-handle (see pictures of the back side).

Sources: Steel - Roller bearing, machine shop, Birmingham, Alabama.

Walnut - Water’s Edge Woods, Athens, Ga.

Price: $950

175mm Black Cherry Burl K-tip Gyuto

Blade: Roller Bearing @HRC 64.

Handle: Octagonal integral black-dyed cherry burl handle with chestnut burl and leather spacers.

Notes: 182g. 49mm deep. A shortened Kiritsuke shape more generally known as a Banno Bunka.

Sources: Steel - Roller bearing, machine shop, Birmingham, Alabama.

Cherry - Athens, Ga.

Chestnut - Balsam Built, Black Mountain, NC.

Price: $900